Steel fencing profiles refer to the various shapes of steel fencing materials, such as flat panels, pickets, tubes, and posts. Pusheng produces a range of hot-rolled fencing and post profiles. Fencing profiles are hot-rolled from a grade of steel suitable for the intended end use.

We mainly supply two profile types of fence posts: Y profile and I profile. According to the gauge applied, the fence posts can be divided into light gauge and heavy gauge post.

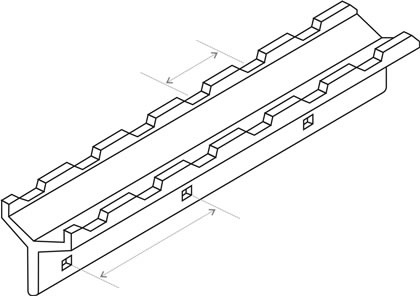

"Y"-profile fencing posts (light gauge)

Pattern

"Y"-section with ribs on the front two legs and holes in the back so as to accommodate wire spacing as per SANS 280: 1970 – "Hole location in fencing posts and droppers". 3.0mm - 5.0mm diameter holes are roughly formed at 50mm to 60mm intervals forming apertures of approximately 5mm per side.

Mass (average)

2.0 kg/m

"Y"-profile fencing posts (heavy gauge)

Pattern

"Y"-section with ribs on the front no holes in order to accommodate wire spacing as per ASTM 702: 1989. This section is recommended for high game fences of 2,4 m and above.

Mass (average)

2.3 kg/m

Refer to SPE 45. Other lengths are available on request.

Bundle size

Approximate 100 units/pack. Packs consist of 10 x 10 sub-bundles and are wire bound by hand.Y profile fencing post

Height: 38mm

Width: 40mm

"Y" post (light gauge) "Y" post (heavy gauge) – no holes

| Area Ixx Iyy Zxx Zyy Nominal mass |

3,835 cm² 9,173 cm4 1,129 cm4 4,475 cm³ 0,903 cm² 3,00 kg/m |

I = Second moment of area

Z = Section modulus

Note: all dimensions are approximate

Use

"Y" post (light gauge)

Support and secure line wires between anchor posts/ poles. Recommended for:

1. Small stock and domestic fences

2. Jackal proof fences

3. Railway line fencing

4. Highway fences

"Y" post (heavy gauge)

Support and secure line wires between anchor posts/ poles. Recommended for:

1.Game fencing

2.Large stock

This is the only "Y" standard where material will be guaranteed against failure.

Installation method of Y Fence Post:

1. These fencing posts are not recommended when the lacing/stringing installation method (wire through the holes) is used. Due to the hot rolling process, burrs are formed in and around the holes resulting in the galvanising being stripped from the wires. Due to the design of the posts, failure of the fence will result in extensive replacement work if a post should fail. Thus no guarantee will be given should the light gauge Y-posts be used for other than their intended use as specified and/or if the fence is stringed.

2. In order to counteract induced vibration on the Y-posts, it is recommended that every fifth post be supported by means of a 50mm steel/wooden pole. Due to the height and the amount of wires on these fences when used as high fences, wind causes the fence to vibrate, resulting in fatigue and breakage the post when not supported.

3. Not suitable for use as anchor or straining posts.

Straightness of the Fence Post:

Material will be supplied un-straightened with straight cut ends on both ends. A commercial straightness tolerance of 5mm maximum deviation over 1 metre will apply.

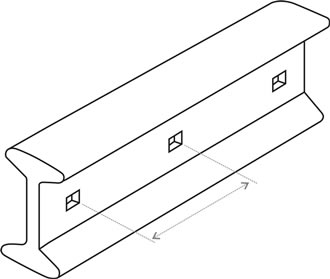

"I" Profile fencing posts

Pattern

"I"-profile with no ribs on the two legs and holes in the centre section so as to accommodate wire spacing as per SANS 280: 1970 – "Hole location in fencing posts and droppers". 5.0mm-10.0mm diameter holes are roughly formed at 50mm to 60mm intervals forming apertures of approximately 5mm per side.

Mass (average)

3.0 kg/m

Bundle size

Approximate 100 units/pack. Packs consist of 10 x 10 sub-bundles and are wire bound by hand.

I profile fencing post

Height: 41mm

Width: 25mm

| Area Ixx Iyy Zxx Zyy Nominal mass |

3,835 cm² 9,173 cm4 1,129 cm4 4,475 cm³ 0,903 cm² 3,00 kg/m |

I = Second moment of area

Z = Section modulus

Note: all dimensions are approximate

Use

Support and secure line wires between anchor posts/ poles. Recommended for:

1. Small stock and domestic fences

2. Jackal proof fences

3. Railway line fences

4. Highway fences

Installation method of I Profile Fencing Posts:

1. Due to the hot rolling process, burrs are formed in and around the holes resulting in the galvanising being stripped from the wires when the lacing/stringing installation method (wire through the holes) is used.

2. Not suitable for use as anchor or straining posts.

Straightness

Material will be supplied un-straightened with one end sharpened for easy installation. A commercial straightness tolerance of 5mm maximum deviation over 1 metre will apply.

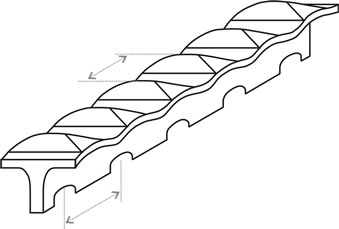

Ridgeback droppers

Pattern

"T"-profile with ridges rolled into the top section.

(To accommodate wire spacing as per SANS 280: 1970 "Hole location in fencing posts and droppers")

Mass (Average)

0.58 kg/m

Bundle size

Approximate 500 units/pack. Packs consist of 10x50sub-bundles and are wire bound by hand.

Back dropper

Use

Support and secure spacing of line wires between line posts.

Straightness

Material will be supplied un-straightened with straight cut ends on both ends. A commercial straightness tolerance of 5mm maximum deviation over 1 metre will apply.

Units per 1 000 kg

| Length mm | Y-profile 2,0 kg/m | Y-profile 2,3 kg/m | I-profile 3,0 kg/m | Droppers 0,58 kg/m |

| 950 | - | - | - | 1,815 |

| 1100 | - | - | - | 1,567 |

| 1250 | - | - | - | 1,379 |

| 1400 | 357 | - | 238 | 1,232 |

| 1550 | 323 | - | 215 | 1,112 |

| 1700 | 294 | - | 196 | 1,014 |

| 1850 | 270 | 235 | 180 | 932 |

| 2450 | 204 | 177 | - | 704 |

| 3050 | 164 | 142 | - | - |

Available Sizes and Lengths

| Fencing Posts | Droppers | ||

| Profile | Y profile 2,0 & 2,3 kg/m | I profile 3,0 kg/m | Ridgeback droppers 0,58 kg/m |

| Holes | With or without | Yes | No |

| Standard lengths (mm) | 1,400 | - | 0,950 |

| 1,550 | - | 1,100 | |

| 1,700 | 1,400 | 1,250 | |

| 1,850 | 1,550 | 1,400 | |

| 2,450 | 1,700 | 1,550 | |

| 3,050 | 1,850 | 1,850 | |

| - | - | 2,450 | |

* Unpainted products on enquiry

* Other lengths on enquiry

The Material Corrosion protection:

In order to supply a cost effective product a low cost paint (coal tar - naphthalene solution) is applied to fencing standards only to render a presentable product without guarantee that it will last for a prolonged period, especially when used in corrosive conditions such as damp areas. The process and paint quality cannot guarantee that surface rust and scratch marks will not occur during handling, installation and use.